Gary Lowe (The Tartan Turner)

with Gary Lowe (https://garylowewoodturner.co.uk/)

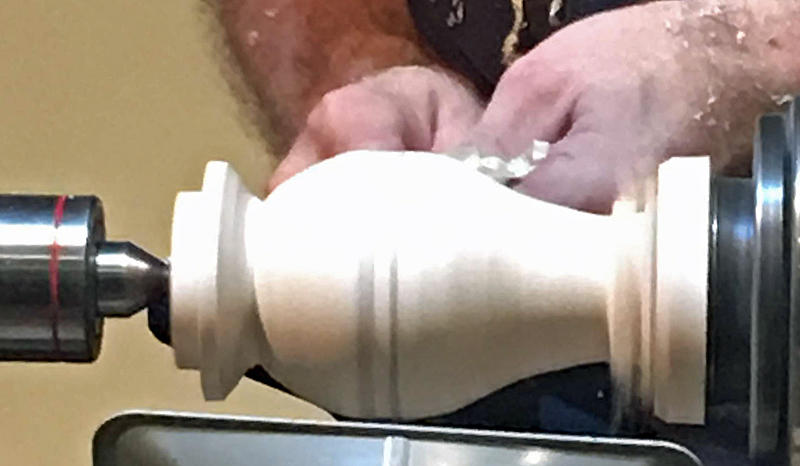

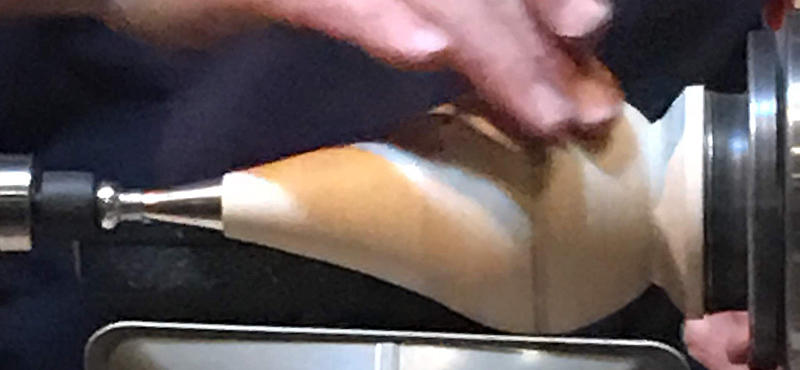

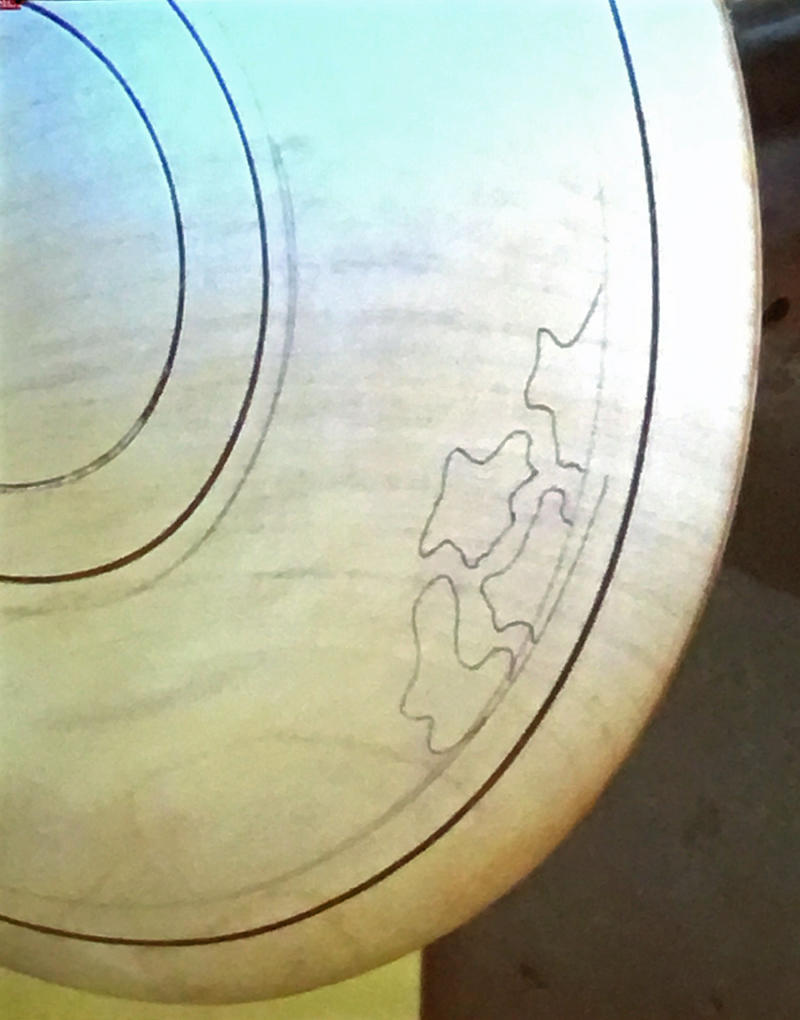

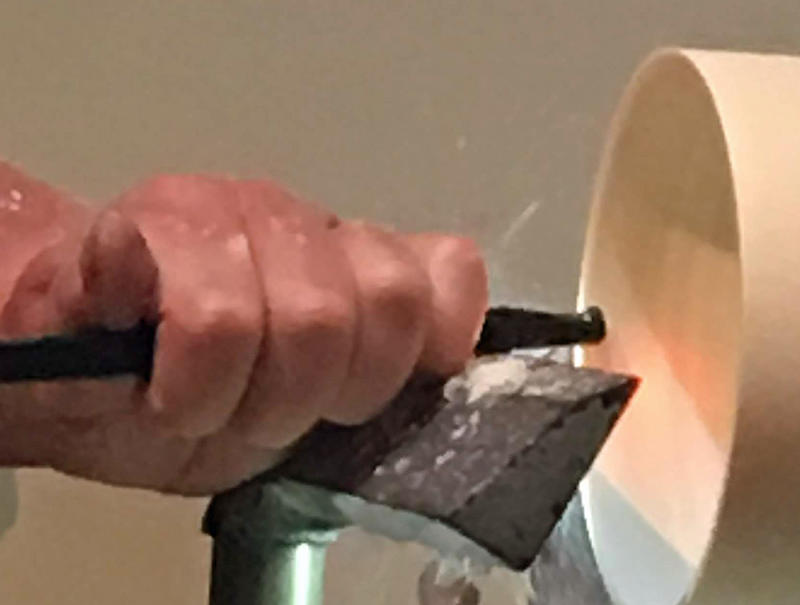

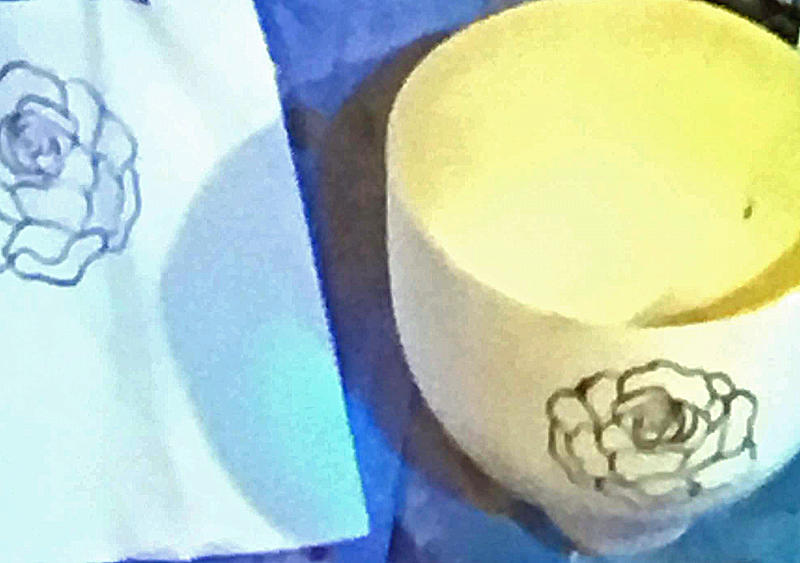

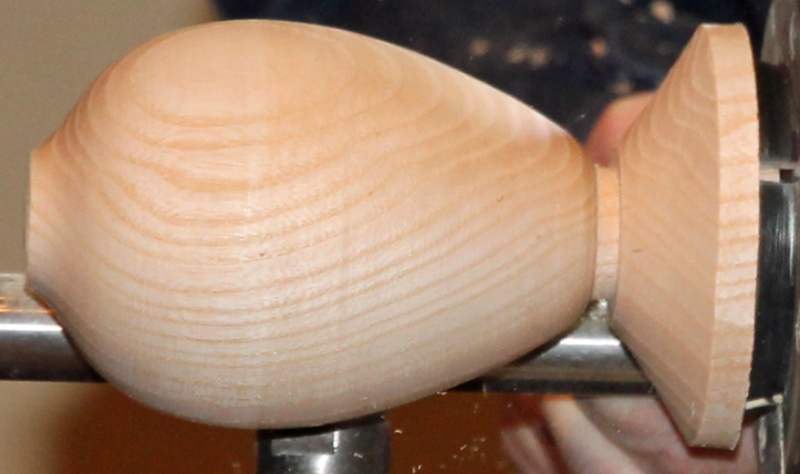

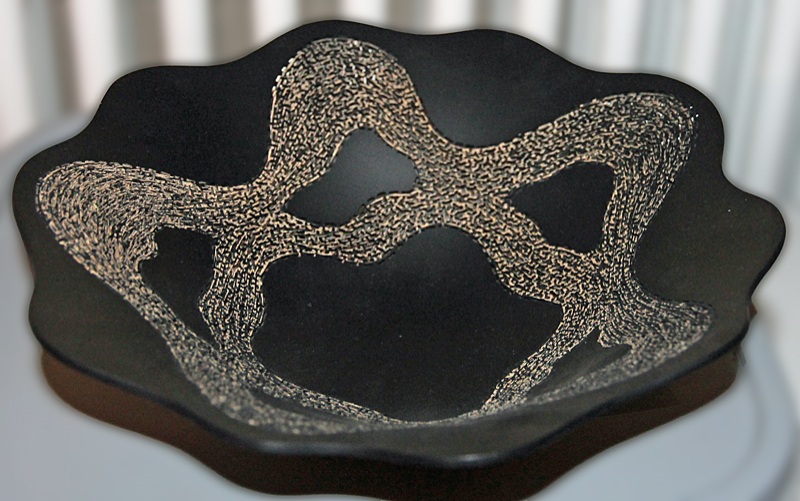

We had the pleasure to watch Gary turn two pieces, a “Saturn” bowl with an off-centre rim and a shield wall platter. He demonstrated his method for turning off-centre and some of the techniques used to achieve different texturing and decorative effects.

Not only was it nice to see pieces being turned from start to finish but he was very engaging with the audience, funny and happy to answer questions.